TECHNOLOGY developed at the University of Strathclyde could help shoppers save £150 million by reducing the 1.9 million slices of ham thrown out by Brits every day.

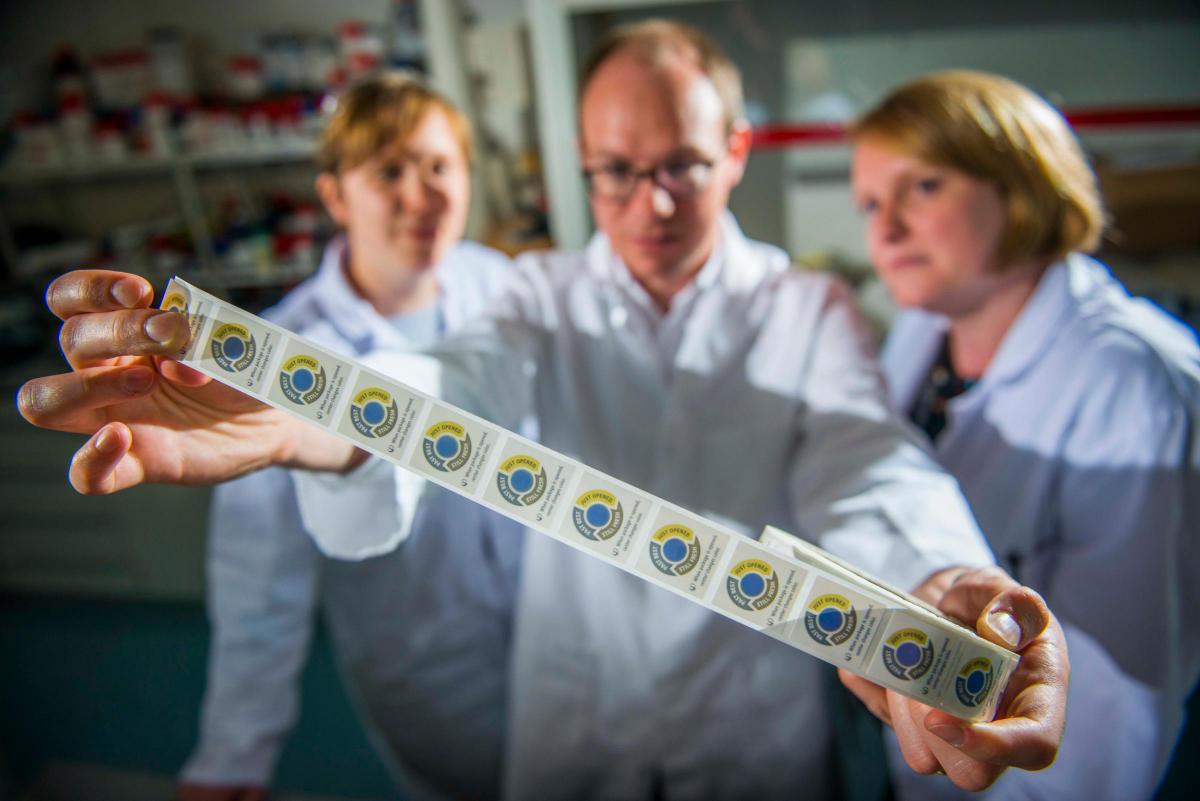

Spin-out firm Insignia Technologies has developed a smart label which helps to track when food is at its freshest. It is currently seeking additional funding to fast track the commercialisation of its technology.

In 2014, Scottish households threw out 360,000 tonnes of food which had could have been consumed.

Government agency Zero Waste Scotland has put the cost of this waste at £1.1 billion, or £460 for every household.

Insignia believes its technology can help cut those numbers and after launching a major trial with a popular Sainsbury’s cooked ham product in 1,100 shops across the UK, bosses believe the business could generate £10 million in annual turnover within the next three years.

David Kilshaw, chief executive of Insignia Technologies, said: “We believe [the technology] will be vital in changing consumer behaviour and tackling the issue of unnecessary food waste, which is undoubtedly one of the biggest economic and environmental challenges the world faces.”

The labels feature time and temperature monitoring and use a colour-changing smart plastic to highlight to consumers when a product is approaching, and has passed, the end of its edible life.

Environment agency WRAP estimates that 70 per cent of the ham thrown away is still edible. Mr Kilshaw said that based on 4p per slice then preventing even one quarter of this would result in a £6.9m saving.

“However, when you take into account the cost of making the product, packaging the product, i.e. using a retail price for a pack of ham, the saving could be closer to a total of £150m per year,” he said.

Based at the life science research centre Biocity in Lanarkshire, Insignia was formed in 2012 through a merger between Dundee-based Insignia Pack and Novas Technologies, a University of Strathclyde spin-out.

Insignia is already generating revenue, with deals in the US and Canada with two of the largest fast-food restaurants in the world to maximise the life of their salads.

And discussions are underway in South America, along with hope of expanding the Sainsbury’s contract.

In 2013, the business won £865,000 of investment, led by Equity Gap along with Highland Venture Capital, the Scottish Investment Bank, the University of Strathclyde and a number of private investors.

Debbie Allan, chief technology officer, explained that the technology does not extend the shelf life of a product, but maximises it.

“After opening a packet of cold meat, for example, the label starts to change colour to tell you how long it has been open in the fridge.

“A packet of ham may have a two week shelf life but what a lot of people don’t realise is that once opened that drops to two or three days. So people either don’t know that and it goes off, or they can’t remember when it was opened.”

Insignia works with manufacturers to establish the precise edible life of a product. Before any food product is launched microbiological testing reveals how long it takes for bugs to grow once packaging has been opened. A percentage of that time is than taken off as a precautionary measure, and this is the timeframe recommended on packs.

By using technology which can identify the temperature of a fridge as well as how long a packet has been opened, shelf-life can be maximised. “We can’t stop food waste where food has gone off, but we can try and tackle that unnecessary waste where food might be edible but people aren’t sure and throw it out,” she said.

While other businesses are pursuing the same space, Ms Allan said none have managed to create a label which can be sold at a price supermarkets are willing to pay, nor has anyone else made a label which can be applied using standard label application on packaging machinery.

“The key USP (unique selling point) for us is that we’ve kept our tech cheap, cost effective, about 1p per label for the ham application. Otherwise supermarkets won’t consider it. Other technologies have failed because they have to hit those cost points.”

Why are you making commenting on The Herald only available to subscribers?

It should have been a safe space for informed debate, somewhere for readers to discuss issues around the biggest stories of the day, but all too often the below the line comments on most websites have become bogged down by off-topic discussions and abuse.

heraldscotland.com is tackling this problem by allowing only subscribers to comment.

We are doing this to improve the experience for our loyal readers and we believe it will reduce the ability of trolls and troublemakers, who occasionally find their way onto our site, to abuse our journalists and readers. We also hope it will help the comments section fulfil its promise as a part of Scotland's conversation with itself.

We are lucky at The Herald. We are read by an informed, educated readership who can add their knowledge and insights to our stories.

That is invaluable.

We are making the subscriber-only change to support our valued readers, who tell us they don't want the site cluttered up with irrelevant comments, untruths and abuse.

In the past, the journalist’s job was to collect and distribute information to the audience. Technology means that readers can shape a discussion. We look forward to hearing from you on heraldscotland.com

Comments & Moderation

Readers’ comments: You are personally liable for the content of any comments you upload to this website, so please act responsibly. We do not pre-moderate or monitor readers’ comments appearing on our websites, but we do post-moderate in response to complaints we receive or otherwise when a potential problem comes to our attention. You can make a complaint by using the ‘report this post’ link . We may then apply our discretion under the user terms to amend or delete comments.

Post moderation is undertaken full-time 9am-6pm on weekdays, and on a part-time basis outwith those hours.

Read the rules here