Orbex, the private space company, has allowed cameras into its working rocket factory in Scotland for the first time.

The behind-the-scenes imagery reveals how the company is using advanced engineering techniques and materials to create the next generation of renewably-fuelled European orbital launch vehicles.

The company also revealed its new mission control centre that will be used to monitor orbital rocket launches from Scotland and other sites, as well as engine tests from its two propulsion test sites.

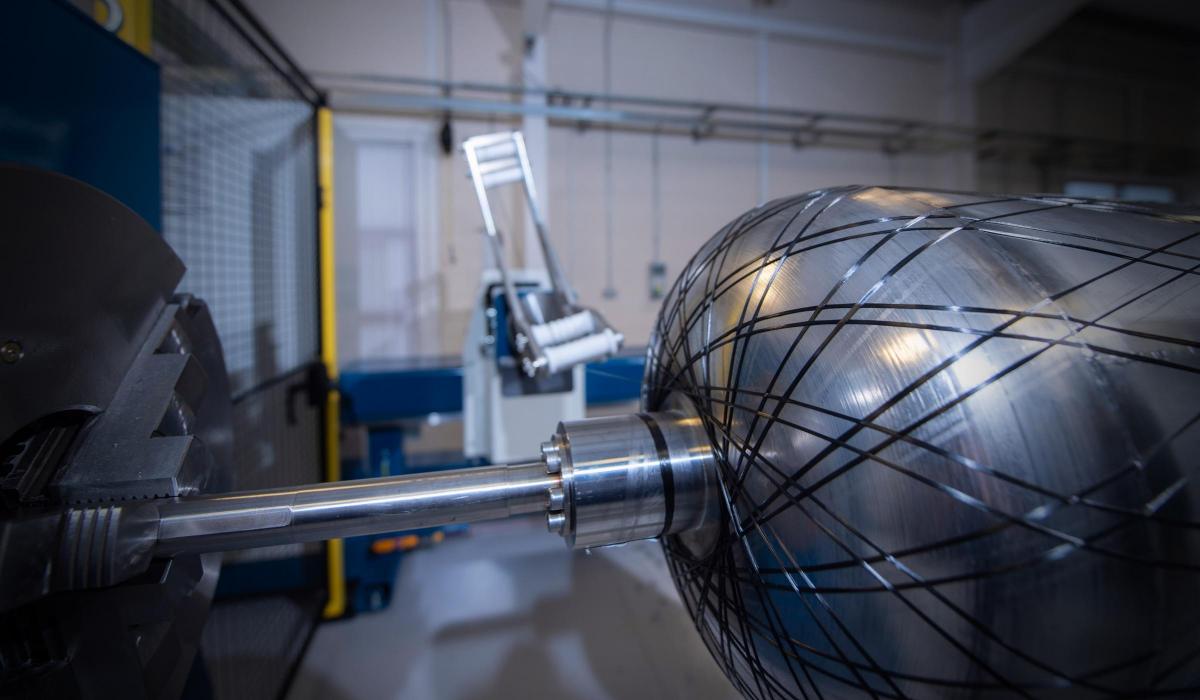

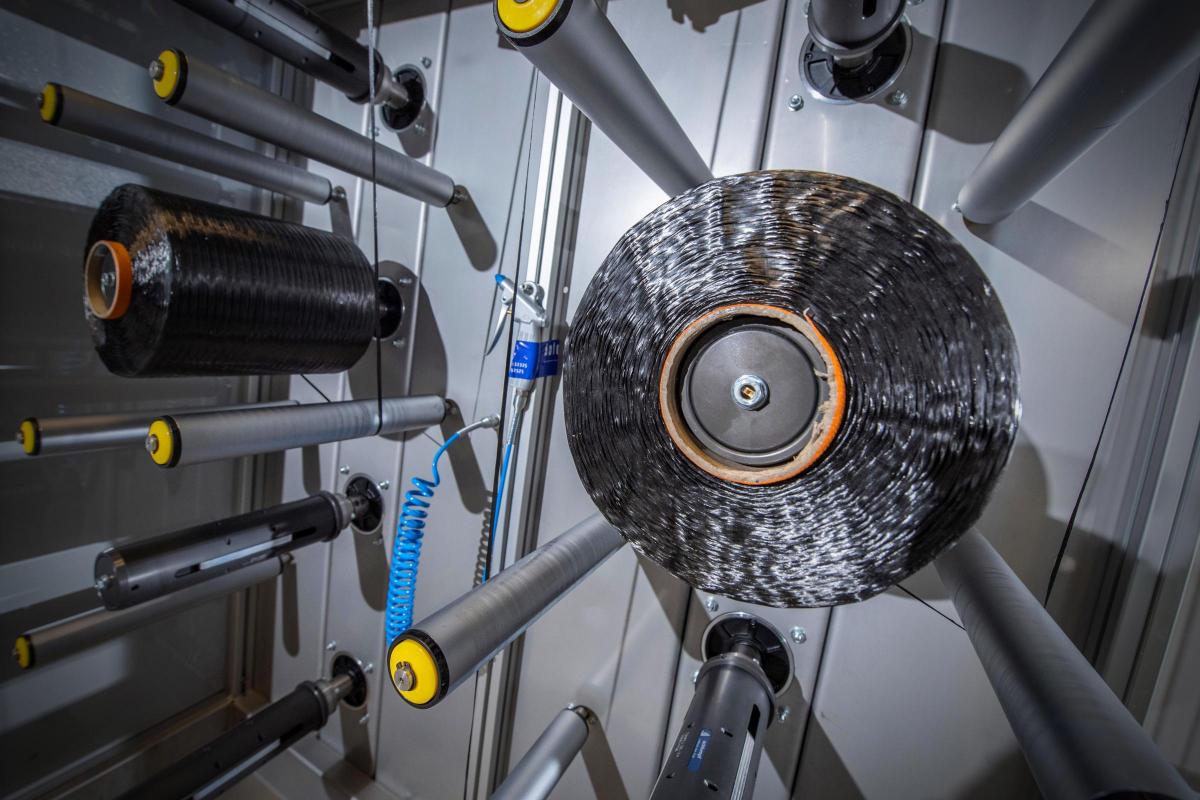

At its Scottish factory, Orbex has installed several new production systems, including one of the largest carbon fibre winding machines in Europe.

READ MORE: Fears over up to 40 launches at remote spaceport

This 18-metre long machine automates the rapid weaving of intricate mixes of materials to build the main rocket structures.

Orbex has worked for several years to investigate and perfect the carbon fibre blend used in the patented construction of its Prime rocket.

Above: Orbex has installed one of the largest high-speed automated carbon fibre winding machines in Europe in its Scottish factory.

Orbex Prime will be 30 per cent lighter than similar sized rockets, allowing acceleration from 0 to 1,330 km/h in just 60 seconds.

Earlier this year, Orbex revealed how it was using 3-D printing to create what are currently the world’s largest single-piece 3-D printed rocket engines.

READ MORE: Scotland's spaceport plans move closer after crofters agree to lease land needed for the project

“We’re creating rockets in a way that hasn’t been done before,” said Chris Larmour, Orbex chief executive. “The whole point of NewSpace - private enterprise getting involved in spaceflight - is to provide faster, better and cheaper access to space. Burning through hundreds of millions of dollars on robotic assembly lines or hundreds of staff to produce heavy, metal rockets is an antiquated approach. Building a modern space business means updating the manufacturing ethos to be faster, more agile and more flexible. That’s what we’re doing here at Orbex.”

Above: An engineer verifies the temperature inside the large-scale Orbex autoclave used to cure carbon fibre structures.

Orbex has also unveiled its new mission control centre at its Forres site.

From here, flight controllers will have access to numerous data streams from the launch vehicle during lift-off and flight, allowing complete remote command and control.

Today, the mission control centre is used to monitor engine tests and simulate flight operations. Orbex has two rocket engine test sites, one in Denmark and one at a secure location in the UK.

READ MORE: Scottish island spaceport site suitability questioned

Prime is expected to be the first rocket to take off from the proposed spaceport in Sutherland.

On August 1, 2019, Orbex’s partner, Highlands and Islands Enterprise (HIE) confirmed that it had signed a 75-year lease option with landowners, the Melness Crofters Estate, to build and operate a spaceport on its land.

The designs for the spaceport, including the eco-friendly Launch Operations Control Centre have been released as part of a public consultation ahead of a formal planning request, expected before the end of 2019.

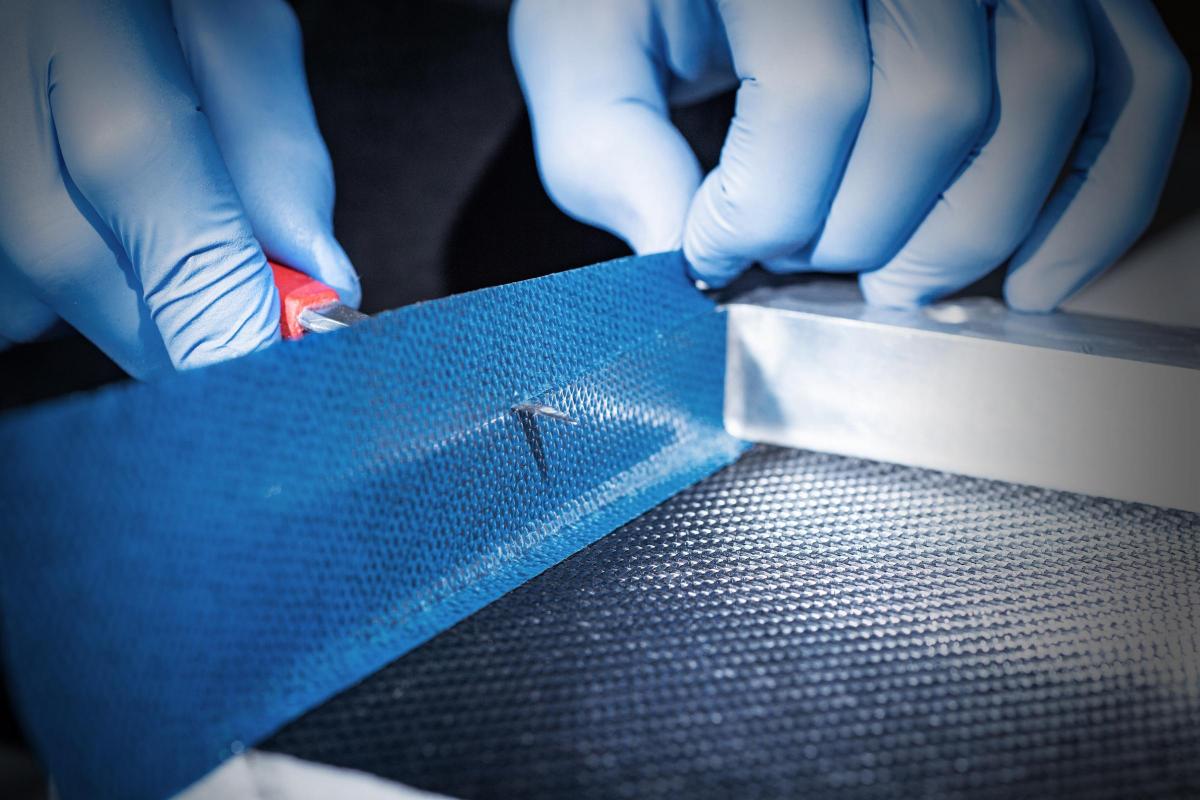

Above: Trimming of pre-impregnated carbon fibre fabric and draping into a component mould. Numerous structural components on the Orbex launcher are built from carbon fibre, making them 50% lighter compared to traditional aerospace materials such as aluminium, and doubling their structural strength.

Above: Orbex’s 3-D printed rocket engine is uniquely manufactured in a single piece without joins. Given the extreme temperature and pressure fluctuations involved in space flight, this gives the engine an advantage over other rocket engines manufactured in two or three sections, which can suffer from weaknesses associated with joining and welding. Weighing just 7.5 kilos, this engine can lift 3.5 tonnes.

Why are you making commenting on The Herald only available to subscribers?

It should have been a safe space for informed debate, somewhere for readers to discuss issues around the biggest stories of the day, but all too often the below the line comments on most websites have become bogged down by off-topic discussions and abuse.

heraldscotland.com is tackling this problem by allowing only subscribers to comment.

We are doing this to improve the experience for our loyal readers and we believe it will reduce the ability of trolls and troublemakers, who occasionally find their way onto our site, to abuse our journalists and readers. We also hope it will help the comments section fulfil its promise as a part of Scotland's conversation with itself.

We are lucky at The Herald. We are read by an informed, educated readership who can add their knowledge and insights to our stories.

That is invaluable.

We are making the subscriber-only change to support our valued readers, who tell us they don't want the site cluttered up with irrelevant comments, untruths and abuse.

In the past, the journalist’s job was to collect and distribute information to the audience. Technology means that readers can shape a discussion. We look forward to hearing from you on heraldscotland.com

Comments & Moderation

Readers’ comments: You are personally liable for the content of any comments you upload to this website, so please act responsibly. We do not pre-moderate or monitor readers’ comments appearing on our websites, but we do post-moderate in response to complaints we receive or otherwise when a potential problem comes to our attention. You can make a complaint by using the ‘report this post’ link . We may then apply our discretion under the user terms to amend or delete comments.

Post moderation is undertaken full-time 9am-6pm on weekdays, and on a part-time basis outwith those hours.

Read the rules hereComments are closed on this article